In the world of manufacturing, understanding the lifecycle of equipment is essential for optimizing production and ensuring longevity. One such piece of equipment that plays a crucial role in various industries is the brush machine. These machines, designed to create brushes for countless applications, have a nuanced lifecycle that begins with design and manufacturing, flows through usage and maintenance, and culminates in eventual replacement or recycling.

At the forefront of brush machine production is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With an impressive 37 years of hands-on experience, this company stands out as a leader in the field, specializing in the production of advanced 2-5 axis machines. Their technical expertise is the result of decades of accumulated knowledge, positioning them as a trusted provider for manufacturers looking to enhance their brush production capabilities. Understanding the lifecycle of brush machines, especially those produced by industry experts like Jiangmen Meixin, can provide valuable insights for businesses seeking efficiency and reliability in their brush manufacturing processes.

Company Overview

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands as a leader in the brush machine industry, known for its specialization in the production of 2 to 5 axis machines. With a solid foundation built over 37 years, the company has accumulated extensive technical knowledge and experience that sets it apart from competitors. This longevity in the market reflects Meixin’s commitment to quality and innovation, making it a trusted provider for various brush manufacturing needs.

The company’s dedication to advancing technology in brush machine production is evident in its ongoing investment in research and development. Meixin continuously seeks to improve its machines’ efficiency, precision, and overall performance. This focus on technological advancement ensures that customers receive cutting-edge solutions tailored to their specific manufacturing requirements.

With a customer-centric approach, Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. strives to foster strong relationships with its clients. The company’s experienced team provides exceptional support throughout the entire lifecycle of the machines, from initial consultation to after-sales service. This commitment to customer satisfaction has contributed to the company’s reputation as a reliable partner in the brush machinery market.

Technological Advancements

In recent years, the brush machine manufacturing industry has seen significant technological advancements that enhance efficiency and precision. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has been at the forefront of these innovations, leveraging 37 years of production experience to introduce cutting-edge features in their 2-5 axis machines. These enhancements have streamlined the manufacturing process, reducing downtime and increasing output, which is vital in meeting the evolving demands of the market.

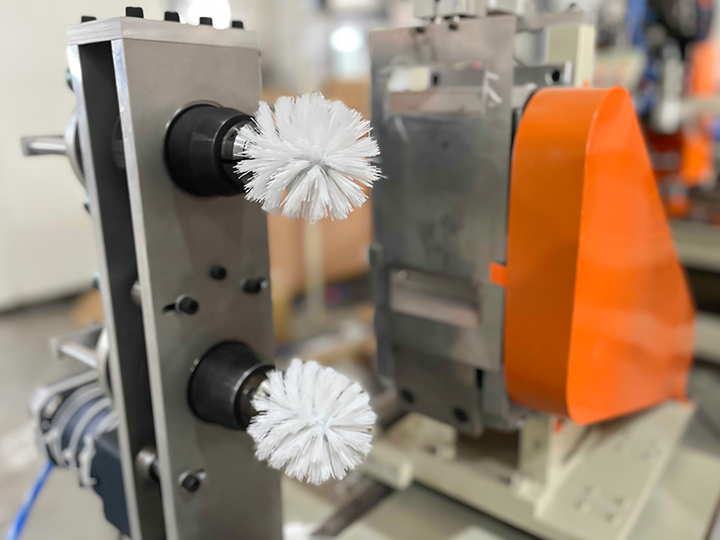

One of the key advancements is the integration of automation and smart technologies into the brush machine production process. Advanced robotics and automation systems have been implemented, allowing for higher precision in brush formation and reducing human error. This not only improves the quality of the brush products but also allows for greater flexibility in production, enabling the factory to quickly adapt to changes in design or consumer preferences without significant retooling.

Additionally, advancements in materials and machine design have resulted in the creation of more durable and efficient machines. The introduction of high-strength materials and innovative engineering designs allows machines to operate at higher speeds and with greater reliability. This durability not only extends the lifespan of the equipment but also minimizes maintenance costs, further enhancing the overall productivity of factories like Jiangmen Meixin, ensuring they remain competitive in a rapidly changing industry.

Production Process

The production process of brush machines at Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. begins with meticulous planning and design. Each machine is tailored to meet specific customer needs, with a focus on efficiency and precision. The company utilizes advanced software and technology to create detailed blueprints that guide the manufacturing process, ensuring that every component is crafted to the highest standards. In the world of manufacturing, one notable example of essential equipment is the Meixin High-Speed Brush Machine which significantly contributes to the production of brushes for countless applications, highlighting the importance of understanding the lifecycle of such machinery for optimizing production and ensuring longevity.

Once the design phase is complete, the factory moves into the manufacturing stage. This involves the careful selection of high-quality materials, which are sourced from trusted suppliers. The materials are then subjected to a series of cutting, shaping, and assembly operations. With 37 years of production experience, the skilled technicians at Jiangmen Meixin expertly oversee these processes, utilizing both traditional techniques and modern machinery to produce durable and reliable brush machines.

Finally, quality control is a critical aspect of the production process. Each machine undergoes rigorous testing to ensure it meets the company’s strict quality standards. This includes functionality tests and safety inspections, allowing the factory to deliver products that not only meet customer specifications but also stand the test of time. The commitment to quality throughout the production process solidifies Jiangmen Meixin’s reputation as a leader in brush machine manufacturing.

Machine Variants

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. offers a diverse range of brush machines designed to meet various manufacturing needs. The company specializes in 2-5 axis machines, which allow for precise and efficient production of different brush types. These machines cater to various industries, including automotive, cosmetics, and household applications. Each variant is engineered to enhance functionality and productivity, making the manufacturing process more streamlined.

The 2-axis machines focus on basic operations, providing essential features suitable for simpler brush designs. These machines are ideal for small-scale production or for manufacturers who are just starting out in the brush-making business. On the other hand, the 5-axis machines bring a higher degree of complexity and versatility, enabling the production of intricately designed brushes with advanced features. This flexibility allows manufacturers to expand their product offerings and enter new markets with ease.

In addition to the axis variants, Jiangmen Meixin’s machines come equipped with advanced technology that includes automation capabilities and user-friendly interfaces. This ensures that operators can quickly adapt to changes in production requirements. Manufacturers benefit from reduced operational downtime and increased efficiency, ultimately leading to higher profitability and growth in the competitive brush-making industry.

Future Outlook

The future of brush machine manufacturing, particularly at Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., looks promising. With 37 years of experience, the company is well-positioned to harness advanced technology and innovative designs to enhance productivity. As industries continue to evolve, the demand for precision-engineered brush machines is expected to rise, driven by both domestic and international markets.

Sustainability will play a crucial role in shaping the future of brush machine production. Companies like Jiangmen Meixin are already exploring eco-friendly practices and materials that reduce waste and energy consumption. By integrating sustainable manufacturing techniques, the company can meet the growing consumer demand for environmentally responsible products while also remaining competitive in the marketplace.

Additionally, advancements in automation and digital technologies are set to transform brush machine operations. Embracing Industry 4.0 concepts, Jiangmen Meixin can enhance efficiency and accuracy through smart machinery and data analytics. This technological leap not only streamlines production processes but also opens new avenues for innovation in brush design and functionality.